Instrumentation@IPFN

The Instituto de Plasmas e Fusão Nuclear (IPFN) of Instituto Superior Técnico, has been developing since 1990 a vertical strategy in R&D in Instrumentation and Digital Computation

IPFN work has been focused in the following areas:

- Specification and Project of Control and Data acquisition Systems;

- Hardware for Control and Data acquisition;

- Software for Control and Data Acquisition;

- Algorithms for Signal Processing;

- Computation and Parallel Processing;

- Communication and transport of timing and real-time events networks.

Transversely to this areas and incorporating the R&D results, several Nuclear Fusion projects were developed, in collaboration with EURATOM and Fundação para a Ciência e Tecnologia (Portugal), in the following scientific domains:

- Visible, X-rays, gamma-rays and neutron spectroscopy;

- Microwave reflectometry;

- Thomson Scattering;

- Plasma Tomography;

- Systems and tools for real-time control of fusion plasmas;

- Control and Data Acquisition Systems;

- Cluster’s e parallel computation.

Activity areas

The following sections briefly describe the IPFN’s activities in Instrumentation and Computation.

Specification and Project of Control and Data Acquisition Systems

IPFN specifies and projects control and data acquisition systems for nuclear fusion experiments, for the European laboratories (JET-EFDA, IPP-Garching, CIEMAT-Madrid, CRPP-Lausanne, IPP.CR-Prague) and Brazilian (INPE e USP), being presently involved in the specification of control and data acquisition systems for ITER.

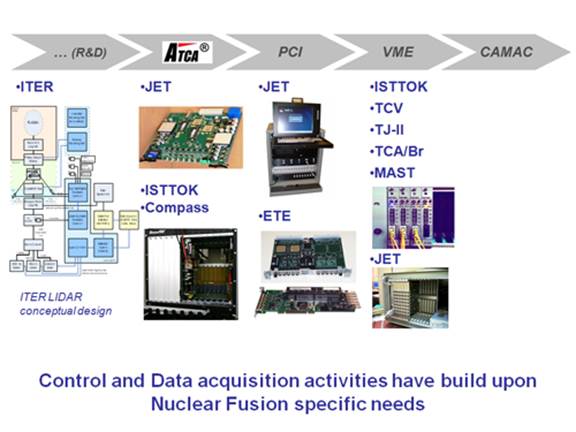

Control and data acquisition hardware

IPFN develops control and data acquisition hardware with the aim of providing the projects with modules and systems with adequate performance and characteristics. The specifications are dictated by the specificities of the experiments, and are usually not available in the industry. Other objectives are cost reduction, good reliability and maintainability.

The developed hardware is based on industrial standards (VME, PCI, ATCA …) with state-of-the-art components (DSPs, FPGAs, DDR2 …) being planed the quality certification in collaboration with ISQ (Instituto de Soldadura e Qualidade).

Control and data acquisition software

IPFN developed a platform for control and data acquisition hardware, FireSignal, available in Linux and Windows operating systems. This software allows the control of experiments in the usual sequence of parameterization, start/end and data collection, as well as continuous control, based on event management. The platform was developed according to a distributed topology and consists in two or more servers containing the parameterization database and collected and/or processed, to which several clients are interconnected by several data transport networks. The clients are the system operators (local or remote and controlling several or the same experiment) as well as the computers that contain the control and data acquisition hardware. The capacity of participation and remote operation of experiments as well as the support for collaboration and remote communication is native to FireSignal and it is managed through a user interface which congregates all the functions.

Algorithms for signal processing

IPFN presently develops algorithms for signal processing in the areas of spectroscopy, microwave reflectometry, tomography and control in fusion plasmas. The codes are developed for processors with algorithm parallelization capacity (FPGAs and DSP farms) as well as conventional processors.

Computation and parallel processing

IPFN developed a computer cluster based on low cost PCs motherboards aimed at the teaching of parallel processing techniques in plasma physics. 3 shows the cluster’s hardware. IPFN is presently collaborating in the development of a GRID computational structure for the European fusion community.

Networks and real-time transport of timing and events

One of IPFN objectives is the development of a communications network which allows the simultaneous real-time transport of data and events with temporal latencies in the microsecond order or below as well as the synchronization of network nodes with a precision inferior to 100 ns. IPFN has developed a proprietary network with these characteristics (implemented in UKAEA) and is presently studying the applicability of the industrial standard 10 Gb Ethernet to this aim.

IPFN facilities

IPFN-IST has a stable instrumentation group. The facilities are well equipped for the development of instrumentation for control, data acquisition, real-time systems and high performance network development.

The IPFN-IST Control and Data Acquisition Laboratory has facilities able to handle the development and production of prototypes and small series. All steps needed to the development, from the scratch, of a Control and Data Acquisition board or System are covered by the facilities equipment and specialized staff (the only exception is the physical production of the Printed Circuit Board which must be done abroad and the purchase of components).

The main development stages covered by the laboratorial facilities are:

- Engineering design of the boards (Schematics/PCB);

- Software/Firmware development;

- Solder paste printing (mask printer and pixel printer);

- Components assembling by Pick and Place machine;

- Automatic soldering;

- Testing.